MateriaLyze (concluded)

MateriaLyze - Knowledge-based Material and Morphology Design for the Next Generation of High Temperature Electrolysis Cells for Green Hydrogen Production

In the project MateriaLyze Montanuniversitaet Leoben and Materials Center Leoben Forschung GmbH research fundamental relationships of solid oxide electrolysis cells for the efficient and sustainable conversion of electrical energy into green hydrogen.

This project was funded by Zukunftsfonds Steiermark within the 14th Call - NEXT GREEN TECH - Energy Systems, Green Hydrogen & Green Mobility, project number: 1407

Project Title

- MateriaLyze - Knowledge-based Material and Morphology Design for the Next Generation of High Temperature Electrolysis Cells for Green Hydrogen Production

Duration

- 01.03.2022 - 28.02.2025

Partners

- Montanuniversitaet Leoben, Chair of Physical Chemistry (Consortium Leader)

- Materials Center Leoben Forschung GmbH (Project Partner)

- AVL List GmbH (Industrial Advisor)

Funding / Call

- Zukunftsfonds Steiermark

- 14th Call - NEXT GREEN TECH - Energy Systems, Green Hydrogen & Green Mobility

Contact

Assoz.Prof. DI Dr. Edith Bucher

Chair of Physical Chemistry

Montanuniversitaet Leoben

Email: edith.bucher(at)unileoben.ac.at

Priv.-Doz. Dr. Roland Brunner

Group Leader Material and damage analytics

Department Microelectronics

Materials Center Leoben Research GmbH (MCL)

Email: Roland.Brunner(at)mcl.at

The research project "MateriaLyze - Knowledge-based material and morphology design for the next generation of high temperature electrolysis cells for the production of green hydrogen" is funded by the Zukunftsfonds Steiermark within the 14th call for proposals - NEXT GREEN TECH - Energy Systems, Green Hydrogen & Green Mobility. The newly created network of the Chair of Physical Chemistry of Montanuniversitaet Leoben and Materials Center Leoben Forschung GmbH in the project creates a critical mass, which enables R&D in the international top field.

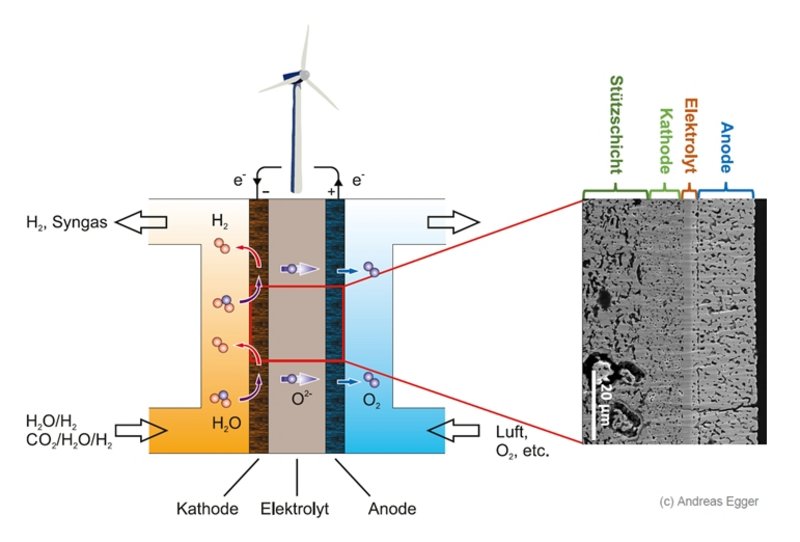

Due to the increasing share of electricity from renewable, partly highly fluctuating energy sources, there is a need to store large amounts of excess energy. However, with the current state of the art energy systems, electrical energy can only be stored to a limited extent. Therefore, innovative future technologies are needed with which electricity from renewable energy sources can be stored in the form of green hydrogen or synthesis gas, i.e. in the form of chemical energy carriers. Solid oxide electrolyzer cells (SOECs) are one of the most efficient and sustainable technologies for converting electrical energy into hydrogen or synthesis gas. However, in contrast to other electrolysis technologies such as alkaline low-temperature electrolysis, SOEC systems have not yet been widely introduced to the market. There is a great need for research with regard to increasing electrolysis performance and long-term stability, which are influenced in particular by the functional materials used in the cell and their morphology (microstructure). The performance and lifetime of the cells are limited - especially at high current densities - by degradation processes of the anode and the anode-electrolyte interface.

Although intensive research is currently being carried out internationally on both the development of new anode materials and the electrochemical or morphological characterization of SOECs, the respective results often stand in an isolated context, so that new knowledge is generated - but not used efficiently. The motivation for the project "MateriaLyze" is therefore the need for a new knowledge-based design approach for SOECs with focus on anode (air electrode) and interface anode-diffusion barrier-electrolyte, which consistently considers fundamental structure-property relationships in the context of material - morphology - electrochemistry. For this project, the extensive know-how and infrastructure of the Chair of Physical Chemistry will be used in the area of synthesis and characterization of fundamental material properties, as well as the preparation and electrochemical characterization of cells. Novel anode materials and innovative electrode designs will be investigated. In the field of material analysis, advanced two/three-dimensional (2D/3D) imaging techniques are used by the Materials Center Leoben. Artificial intelligence (AI)-based models are developed and applied in this project for quantification of the large image data sets and for sufficient statistical evaluation of the 2D/3D morphology data (e.g. pore distribution, tortuosity, etc.). The common goal of the project partners is a knowledge-based design approach that takes into account fundamental material properties and morphological-chemical aspects of the anode and the anode-electrolyte interface as well as electrochemical properties of the cell.