Design-SOEC

Knowledge-based design of solid oxide electrolysis cells for optimized hydrogen production

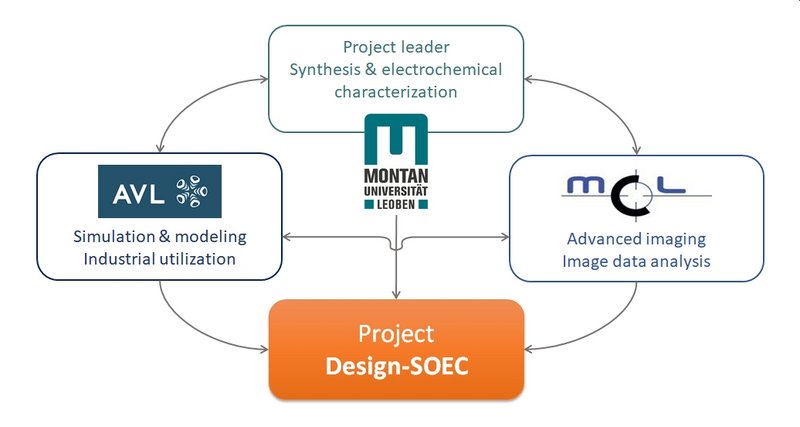

In the project Design-SOEC Montanuniversitaet Leoben, Materials Center Leoben Forschung GmbH and AVL List GmbH are working on the development of a knowledge-based design approach for solid oxide electrolysis cells with optimized core components and improved reliability, energy efficiency and lifetime.

This project is funded by the Austrian Research Promotion Agency (FFG) / Klima- und Energiefonds within the 8. Call Energieforschung, project number: F0999896681

Project Title

- Design-SOEC - Knowledge-based design of solid oxide electrolysis cells for optimized hydrogen production

Duration

- 01.04.2023 - 31.03.2026

Partners

- Montanuniversitaet Leoben, Chair of Physical Chemistry (Consortium Leader)

- AVL List GmbH (Project Partner)

- Materials Center Leoben Forschung GmbH (Project Partner)

Funding / Call

Contact

Assoz.Prof. DI Dr. Edith Bucher

Chair of Physical Chemistry

Montanuniversitaet Leoben

Email: edith.bucher(at)unileoben.ac.at

Dr. Reinhard Tatschl

Group Leader Advanced Simulation Technologies

AVL List GmbH

Email: reinhard.tatschl(at)avl.com

Priv.-Doz. Dr. Roland Brunner

Group Leader Material and damage analytics

Department Microelectronics

Materials Center Leoben Research GmbH (MCL)

Email: Roland.Brunner(at)mcl.at

The storage of large amounts of surplus energy is a key factor in the energy transition due to the increasing share of electricity from renewable, sometimes highly fluctuating energy sources. However, with the current state of the art energy systems, electrical energy can only be stored to a limited extent. Therefore, new innovative storage technologies, such as electrolysis and/or power-to-gas, are necessary. High-temperature electrolysis cells (SOECs) represent one of the most efficient and sustainable technologies for converting electrical energy into hydrogen or synthesis gas. However, unlike other electrolysis technologies such as alkaline electrolysis, SOEC systems have yet to be widely commercialized.

The design approach for state of the art SOEC cells is heavily based on experimental studies. The results are typically used as the basis for material and microstructure variations to incrementally improve the cells. Although work on microstructural characterization of the cells, as well as modeling/simulation, is performed in addition to electrochemical characterization, the respective results are often in an isolated context, so that new knowledge is generated - but not utilized.

The motivation for the project "Design-SOEC" is the need for a new development approach for SOECs, which combines competences in electrode/cell preparation and electrochemical characterization with detailed microstructural analyses and comprehensive simulations. The overall goal of the project is to develop a knowledge-based design approach for SOECs with optimized core components and improved reliability, energy efficiency and lifetime. In particular, the design approach should also enable the scalability of the results from studies on button cells to cells on an industrially relevant scale.